|

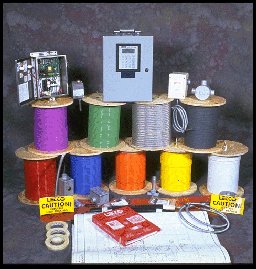

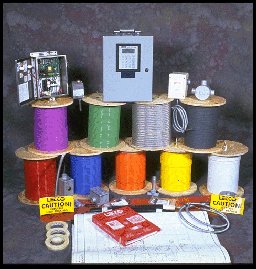

Large Stock - Application Assistance - 30 Years Experience

SELF-REGULATING Freeze Protection up to 250°F

CONSTANT WATTAGE Up to 500°F

MINERAL INSULATED Up to 1000°F

IMPEDANCE HEATING Up to 1000°F High Temperature Applications

Calculate Heat Requirements for Maintaining A Pipe Temp on the Web:

@ www.thermalinc.com/math/pipetrace.htm

Call us at (901) 452-4516 or

E-mail us at thermalinc@thermalinc.com

Copyright 2000 Thermal Equipment Sales Co. Inc.

Self-Regulating

Advantages:  Cut to fit in the field.

Possible lower operating cost.

Possible lower installation cost.

Wide variety of wattages

Most tolerant to overlapping

Low Cost

Cut to fit in the field.

Possible lower operating cost.

Possible lower installation cost.

Wide variety of wattages

Most tolerant to overlapping

Low Cost

Disadvantages:

High start-up currents

Difficult to precisely control temperature

Not well suited for procsss control

Low design temperatures

Self-regulating cable

has two parallel conductors or bus wires

extruded in a polymer core. The core's resistance changes porportionally with

temperature.

The key to understanding Self-regulating cable is the output adjusts proportionally

to the cable sheath temperature not the temperature of the pipe heated.

There is no direct feed back for the pipe temperature.

Most self-regulating cables are designed to give their rated wattage at 50 degrees F.

The wattage output will exceed the rated wattage when the cable temperature is

below 50 degrees and the lower the cable temperature the larger this wattage i.e. amperage is.

INRUSH!! A high start up current is the result. Tight temperature control

is also more difficult with self-regulating cable, because the wattage output is always changing

seeking 50 degrees F on the cable not the pipe or fluid in the pipe.

Self-regulating cable works quite well for freeze protection

applications. Freeze protection and low temperature applications that do not require

very tight control.

The inrush can be considered on the design of wiring and breakers, and there are some other

cost savings to consider. We always recommend a thermostat on every cable we sell. However,

when there are several very short runs or several pipe size changes one ambient

thermostat can save on a job.

Self-Regulating Cable

| Model #

| Temperature Range

| Wattage

| Voltage

| Jackets

| | SLCAB Series

| 150 Max Operating Temp

200 Degrees F

| 3 to 10 Watts

| 120, 208, 240 & 277

| B= Tinned Copper Overbraid

BP = Braid with Thermoplastic Elastomer OverJacket

BF = Braid with Fluoropolomer OverJacket

S = Stainless Steel Overbraid

|

| SLMCAB Series

| 150 Max Operating Temp

200 Degrees F

| 5 to 15 Watts

| 120, 208, 240 & 277

| |

Visit our Math Page to:

Calculate Heat Requirements for Maintaining Pipe Temp

@ www.thermalinc.com/math/pipetrace.htm

BACK TO TOP

Return to our Home Page

Call us at (901) 452-4516 or

E-mail us at thermalinc@thermalinc.com

Copyright 2000 Thermal Equipment Sales Co. Inc.

Constant Wattage

Advantages:

Cut to fit in the field.

Easily controlled Built in cold length at every power connection

Wide variety of wattage outputs

Low cost

480 Volt Cable available

Design Temperatures up to 500° F

Built in cold length at every power connection

Wide variety of wattage outputs

Low cost

480 Volt Cable available

Design Temperatures up to 500° F

Disadvantages:

Requires pipe sensing thermostats

Can NOT be overlaped

Constant Wattage Cable is made up with two parallel conductors or wires. These wires have

a heater wire wrapped around and connected in approximately 2-foot intervals in parallel.

This design provides constant wattage output or a uniform output all along its length.

The heater wires are designed such that if any section of cable should fail the rest of

the heater would continue to operate without change.

Constant wattage cable should NOT be overlaped. The effect of double the wattage where

the cable crosses will cause high temp failures.

The constant wattage output makes maintaining higher and more accurate process

temperatures easier.

This cable is well suited for freeze protection

and many low temp process control applications.

This cable can be cut in the field. When terminated the last 2-foot heater section becomes

a cold sections "unheated".

This provides an unheated section of cable to penetrate the insulation, enter the

junction box and make up power connections.

Constant Wattage Cable needs a thermostat on each pipe and each pipe size in order

to maintain accurate temperature control.

Constant Wattage Cable

| Model #

| Temperature Range

| Wattage

| Voltage

| Jacket

| Overbraid

|

| FECAB

| 400° Max

Operating Temp

| 3 to 12

Watts/foot

| 120, 208, 240,

277 & 480

| Teflon@

| B= Tinned Copper Overbraid

SS = Stainless Steel Overbraid

| | KECAB

| 500° Max

Operating Temp

| 3 to 12

Watts/foot

| 120, 208, 240,

277 & 480

| Teflon®

w/Teflon® Overjacket

| B= Tinned Copper Overbraid

SS = Stainless Steel Overbraid

|

| KKCAB

| 500° Max

Operating Temp

| 4 to 18

Watts/foot

| 120, 208, 240,

277 & 480

| Heat Fused Polyimide

| B= Tinned Copper Overbraid

SS = Stainless Steel Overbraid

| | KMCAB

| 500° Max

Operating Temp

| 4 to 18

Watts/foot

| 120, 208, 240,

277 & 480

| Polimide over Fiberglass

| B= Tinned Copper Overbraid

SS = Stainless Steel Overbraid

| |

Visit our Math Page to:

Calculate Heat Requirements for Maintaining Pipe Temp

@ www.thermalinc.com/math/pipetrace.htm

|

| |

We've seen your application. Call Us for application Assistance

(901) 452-4516